Specifications:

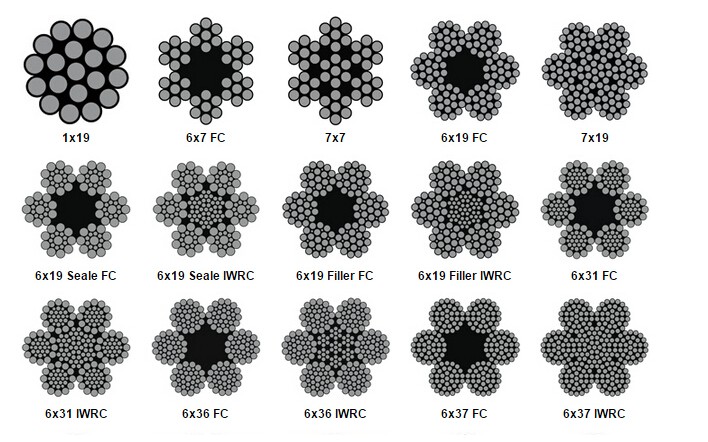

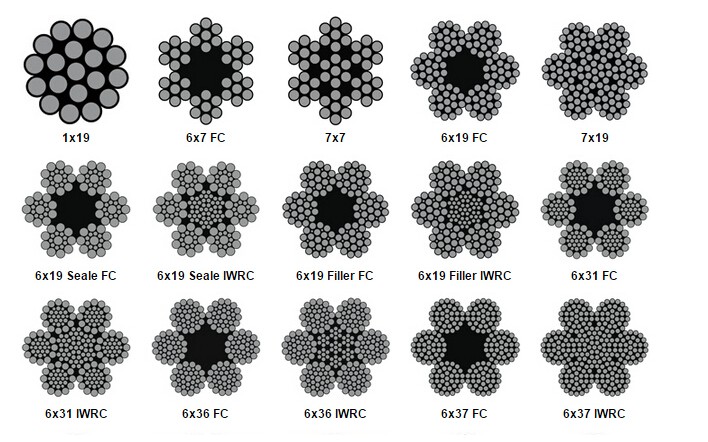

Construction:1 x7,1 x19,1 x37,7 x7,7 x19,6 x19S/W+IWRC,6 x36SW+IWRC,19 x7 etc.

Surface:bright, cloudy,plain,black

Packaging:pvc or wooden reel, pallets, wooden box or customized wooden or plastic spools and craft paper (inner) stong wooden pallet or according to request(outer)

Standard:ASTM A240,GB/T3280-2007,JIS4304-2005,ASTM A167,EN10088-2-2005

Tensile strength:1470MPa/1570MPa/1670MPa

Main application:lifting, fixing, cableway, hanging,supporting, refloatation. haulage, etc

Different of core

FC stands for fiber core

Made of natural or synthetic fiber, which c, , , , , , , , , , , , , , , , , , , , , , , , , an provide excellent flexibility and resistance to contact pressure.

The fiber core can store lubrication to reduce the friction between wire strands effectively. Meanwhile, the fiber core makes the rope lower deformable with low elastic rope elongation.

WSC is abbreviation of wire strand core. WSC ropes features better heat resistance than FC ropes, meanwhile, increase metallic section provide added 15% of strength.

However, WSC steel ropes are less flexible than those with fiber cores.

IWRC is short for independent wire rope core, which strengths the rope, reduce tensile stress in individual wires as well as makes the ropes more resistant to crushing.

At the same time, IWRC wire ropes have the maximum heat resistance than others FC or WSC ropes.

Cross laid wire rope means each wire of different layers contacts in points and has relatively large spaces between wires.

It is extremely flexible and generally used in slings. Compared with parallel laid wire rope, this one has smaller contact area which makes it easier to fail due to fatigue and shear over time.

Parallel laid wire rope has wider contact areas with minimal breaks caused by inside abrasion.

They boast low bending fatigue and higher breaking load without any destruction of strand shapes taking advantages of their tight structure. Normally, parallel laid wire ropes can be classified into four types: seale type (S), filler wire type (F), warrington type (W) and warrington & seale type (WS) as shown below:

|

Application |

Name |

Construction |

|

for aerospace controls |

wire rope |

6x7, 6x19 |

|

for elevator lifting |

wire rope |

6x19S, 8x19S |

|

vertical well hoisting purposes |

linear contact lay wire rope |

6x19S, 6x19W, 6x25Fi, 6x26WS, 6x31WS, 6x36WS, 6x41WS |

|

multi-strand rope |

18x7, 17x7 |

|

blanced wire to well |

flat ropes |

6x4x7, 8x4x7, 8x4x9, 8x4x19 |

|

wire rope |

6x37, 6x37S, 6x36WS |

|

multi-strand rope |

17x7, 18x7, 34x7, 36x7 |

|

for winch purposes |

wire rope |

6x7, 6x9W |

|

bearing to tank and cableway |

full-lock coil ropes |

see the standards of facial contacted wire rope |

|

multi-strand rope |

18x7, 17x7 |

|

wire rope |

6x7 |

|

hoisting to slope |

linear contact lay wire rope |

6x36WS, 6x37S, 6x41WS, 6x49SWS,6x55WS |

|

for petroleum drilling purposes |

linear contact lay wire rope |

6x19S, 6x19W, 6x25Fi, 6x29Fi, 6x26WS, 6x31WS, 6x36WS |

|

rubber belt conveyer, cableway |

linear contact lay wire rope |

6x19S, 6x19W, 6x25Fi, 6x29Fi, 6x26WS, 6x31WS, 6x36WS, 6x41WS |

|

fishing industry |

wire rope |

6x24, 6x24S, 6x24W, 6x19, 6x19S/W, 6x31WS, 6x36WS, 6x37, 6x37S |

|

lashing |

wire rope |

6x24, 6x24S, 6x24W |

|

for crane purpose |

linear contact lay wire rope |

6x19S+IWR, 6x19W+IWR, 6x25Fi+IWR, 6x36WS+IWR, 6x41WS+IWR |

|

multi-strand rope |

18x19, 18x19S, 18x19W, 34x7, 36x7 |

|

linear contact lay wire rope |

6x19W/S, 6x25Fi, 6x29Fi, 6x26SW, 6x31WS, 6x36WS, 6x37S, 6x41WS, 6x49WS, 6x55WS, 8x19S/W, 8x25Fi |

|

point contact wire rope |

6x19, 6x37 |

|

for boat loading and unloading |

linear contact lay wire rope |

6x24S/W, 6x19S/W, 6x25Fi, 6x29Fi, 6x31WS, 6x36WS, 6x37S |

|

point contact wire rope |

6x19, 6x37 |